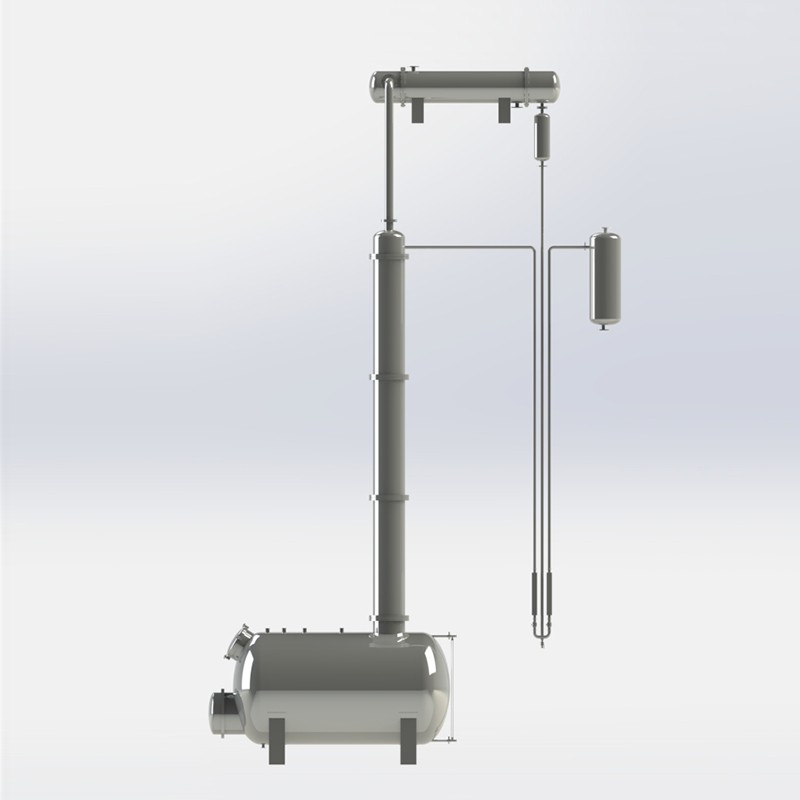

Solvent Distillation Column

- JOSTON

- WENZHOU, CHINA

- 35 DAYS

- 20 SETS/MONTH

solvent distill column is used for distillate low concentration of the solvent by distilation to remove some impurities and moisture,and get the maximum concentratorion of high degree solvent .

Solvent distill column is used to separator and distill the different solvent compenet from the solvent .

How does the Solvent distill column working principle?

Because the boiling points of each component in the raw material are different, so as long as through multiple partial condensation and partial evaporation, the separation between different components can be realized. In detail, the multicomponent solution is introduced into the stainless steel rectifying tower and heated, then some liquid will be evaporated. Because the boiling points of each component are different, of course, the component with low boiling point will evaporate first, and when the steam is cooled, part of it will condense and then change into liquid.

2. Solvent distill column operation:

In order to ensure the distillation effect, the top of the stainless steel distillation tower must have downflow liquid, and the bottom of the tower kettle must have continuous rising steam, and make each layer of the tower plate gas-liquid contact, so as to carry out mass and heat exchange, realize partial evaporation and partial condensation. In this way, the components with low boiling point in the rising steam become more and more concentrated, and the required pure gas can be obtained. However, the components with high boiling point in the downflow liquid become more and more concentrated, which is the way to get pure liquid.

The equipment including the following unit :re-boiler, tower column,condenser ,sub-cooler,solvent collection tank and pipeline

Model Item | JH200 | JH300 | JH400 | JH500 | JH600 | JH800 |

Tower Column diameter mm | 200 | 300 | 400 | 500 | 600 | 800 |

Tower height mm | 7200 | 7200 | 7200 | 7200 | 7200 | 9000 |

Re-boiling tank volume L | 600 | 1000 | 1500 | 2000 | 3000 | 4000 |

Feeding concentration for alcohol | 30%-50% | |||||

Output concentration for alcohol | 93%-95% | |||||

Output capacity for alcohol kg/h | 60-80 | 90-100 | 120-150 | 200-300 | 350-400 | 550-600 |

Dimension M | 2.5X0.8X10 | 2.6X0.9X10 | 2.8X1.0X11 | 3.0X1.0X11 | 3.5X1.4X12 | 4.2X1.714 |