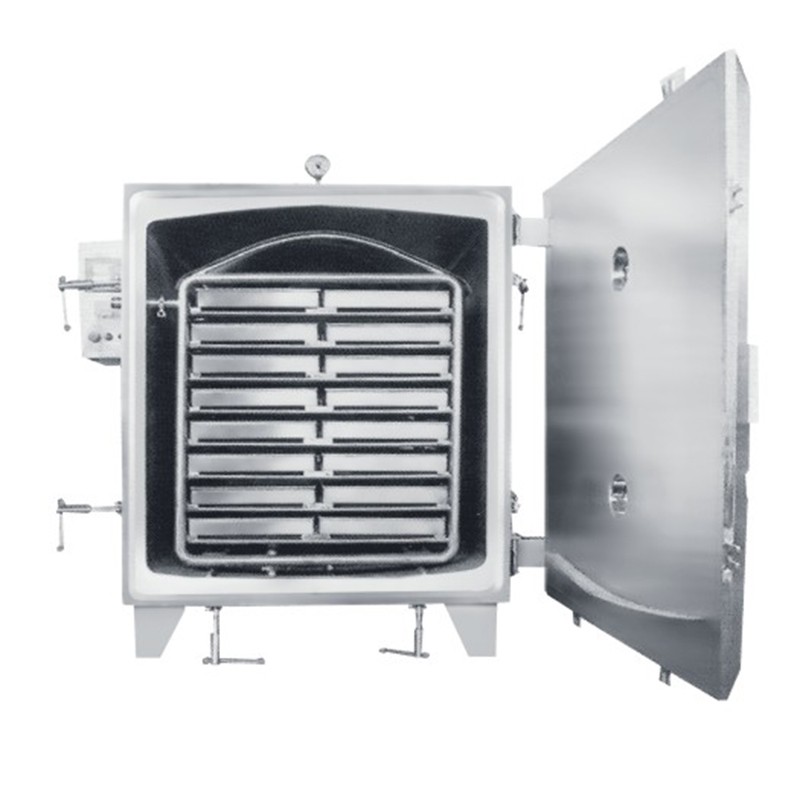

Vacuum Drying Machine

- JOSTON

- WENZHOU, CHINA

- 35 DAYS

- 20 SETS/MONTH

This equipment dry the product in the low temperature and not destroy the temperature-sensitive product .

vacuum drying machine can be used for low temperature drying and organic solvent recovery. Heat source can be steam, hot water and thermal oil. It is specially suitable for drying materials that is easily oxygenated during drying.

in the drying chamber, material will be dried under vacuum condition. Under the vacuum condition, the boiling point of material solution will reduce. It will increase impetus for heat and mass exchange. Therefore for certain heat exchange amount, it can save heat exchange area of evaporator

Material is under static condition during operation of the equipment, which is benefit for keeping initial status of material. Intermittent operation can adjust process conditions at any time.

On the top of vacuum dryer, heating system is arranged to tackle the problem of return of condensed water, in addition, air suction is arranged at the side to improve drying efficiency.

vacuum drying machine technology data

Model Item | FZG-10 | FZG-15 | FZG-20 |

Layers of backing support | 5 | 8 | 12 |

interval(mm) | 122 | 122 | 122 |

Size of baking tray(mm) | 460×640×45 | 460×640×45 | 460×640×45 |

Quantity of baking tray | 20 | 32 | 48 |

Working pressure inside the pipe of baking support(MPa) | ≤0.784 | ≤0.784 | ≤0.784 |

Temperature inside the chamber(°C) | ≤150 | ≤150 | ≤150 |

Degree of vacuum inside the chamber when operation in idle, MPa | ≤30 | ||

Under the vacuum condition of 30and110°C ,evaporation rate of water(kg/m2,h) | 7.2 | ||

Model and power of vacuum pump when condenser is used(kw) |

2X-70A 5.5kw | 2X-70A 7.5kw |

2X-70A 7.5kw |

Outer size of drying chamber(mm) | 1924×1720×1513 | 1513×1924×2060 | 1924×2500×1513 |